BioHack Adcademy(BHA) 2022

A Personal Documentation of BHA 2022

4/2(Sat) Prototype 1

To understand and speculate the works of gear, I thought about making prototype by assembling gears.

とりあえずモデルを作ってみる。それがうまく動けば、3Dモデルソフトでその再現を目指したい。

Therefore, I came back Akihabara!!

I visited Sengoku Densho again.

A variety of gears are soldon the 3rd floor.

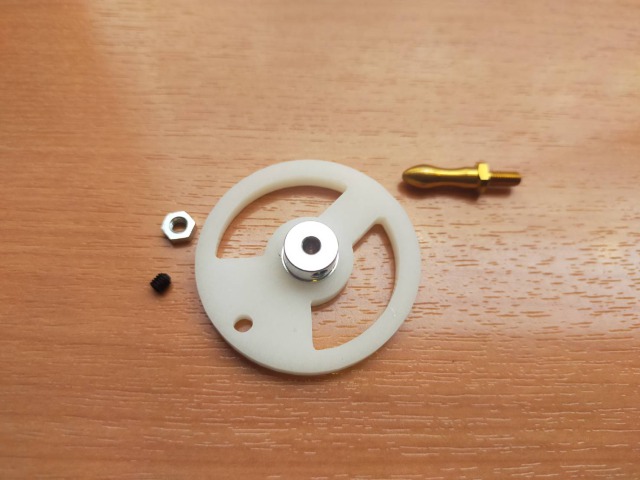

What I bought

・Spun gear (50 teeth, 1.0 module) ¥649

・[Handle(40mm, 3.0module)](https://www.sengoku.co.jp/mod/sgk_cart/detail.php?code=4AZU-JFFG() ¥682

・Bevel gear (? teeth, 6.0 module) ¥490

・Pinion gear (14 teeth, 1.0 module) ¥363

・Screw rod (3mm*29mm) * 2 = ¥594

・Stainless shaft (6mm) ¥480 -> (5mm) ¥480

Note: I couldn’t find plate-shaped materials in Sengoku Densho that is suitable to fix gears. I should look it for other shops.

Additional items purchased

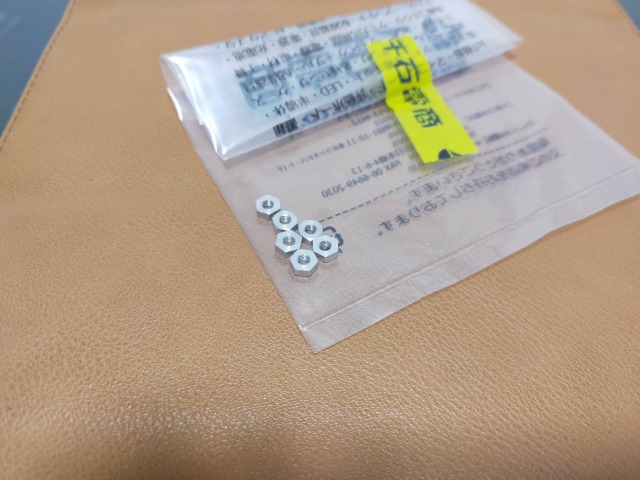

・Screw rod (3mm*59mm) ¥396

・Hexagon head nut(3mm) * 6 = ¥60

・Mini Glue ¥396

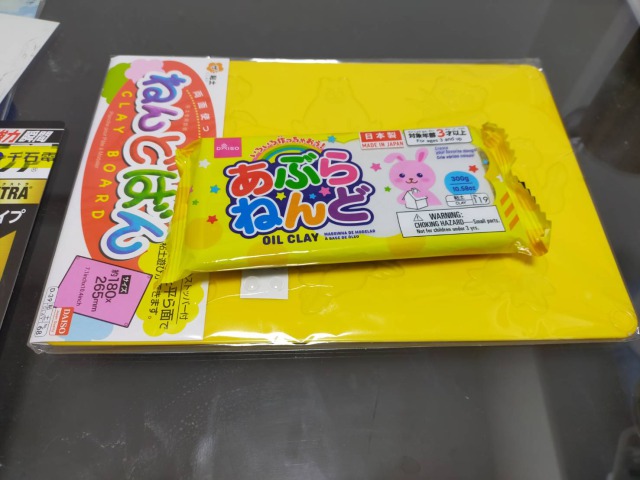

・Clay(ダイソー)¥110

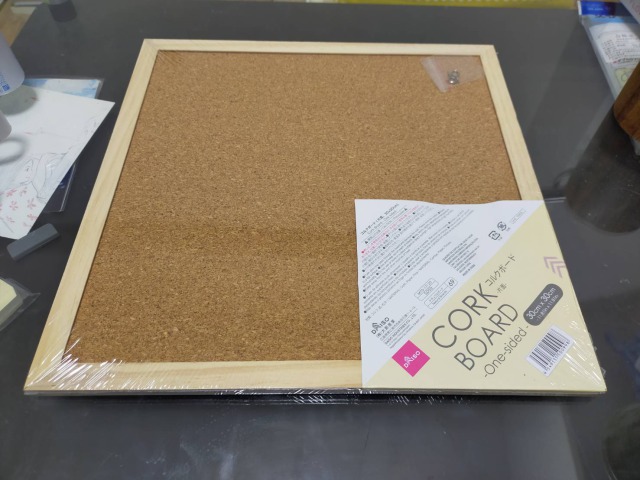

・Cork Board(ダイソー) ¥110

Note: I bought clay and cork board, as I thought it could be used as a foundation.

Total amount: ¥4,676

Handle

Spun gear

Connect handle and spun gear with screw to move together.

Screw rod

Pinion gear

Unfortunately, it appears that 6mm shaft is too big to fit after buying it. So, I had to go back the shop to changed it to 5mm. This time, however, it was still not match with the hole of bevel gear. I will have to deal with this problem later (fill a gap with something?).

My choice that using clay as foundation was entirely mistake, though it helped to adjust the positions of each parts. It was too soft to fix the gears and polls…

土台がよわよわすぎた……😭😭

Therefore, I will make foundation with material which is harder next time.

Not working version (pinion gear and bevel gear are not meshing well)

.gif)

After adjusting the height of the bevel gear, then it worked (just a little bit…).

.gif)

Anyway, it was good to know that the gears’ teeth are meshing and able to move, even though it moved awkward.

Radio controlled car centrifuge?

Maybe using motor-kits for radio controlled car is easier…?

However, I will try to make hand-cranked centrifuge firstly as challenge.

こっちを使ったほうがよっぽど早いのでは、という誘惑(3000円くらいだし)……。しかしひとまずは一から作ることに挑戦してみたい。

Reviews & Tasks

・コルクボードで土台を作ってみる。もしそれがうまくいかなければ、別の素材を探す。

・棒の隙間を埋める

・今の歯車の数では回転数がかなり遅いと思われる。より速い回転を得たければ、もっと歯車の数を増やす必要がある。

・ハンドルが小さくて回しにくいので、これも改良したい。

・Make foundation by cork board. If it fails, I will look for other materials.

・The rotation speed of above model which has a few gears seems to be very slow. If I want it to be faster, it is necessary to use more gears.

・The handle is too tiny to handle. I want to improve this point.

Memo

備忘録

・もはや何でも遠心分離機に見えてきた

・だんだん部品の名前を覚えてきた。ウォームギア、かさ歯車、シャフト etc…

・歯車の仕組みを理解することや、さまざまな種類があるのが面白くて、歯車にはまってきた。ただ、あまり歯車自体に夢中になると本来の目的を忘れそうなので、程々に。

・I became to see everything around me which is able to spin and with gears as usable for centrifuge. I felt interesting in such change of my point of view.

・I have memorized some of names of gears and parts: worm gears, bevel gears, shaft, etc.

・I have been hooked on gears because I find it interesting to understand how they work and the different types of gears. I should careful not to dedicate too much to only gears because my main purpose is replicate/recreate classic-style centrifuges, not learning gears itself!